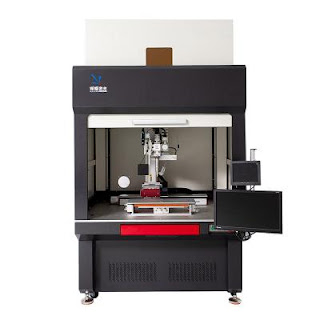

Consumer Electronics Laser Welding Machine

Consumer Electronics Laser Welding Machine Laser Welding Machine Description : Model HY-3000w Laser source 3000w Name Hot sale good quality Consumer Electronics laser welding machine XYZ Travel Customizable R Axis Optional, 360° rotation Position Accuracy ±0.02mm Repeatability Accuracy ±0.01mm Motion Source Servo motor Max Speed 500mm/s Cooling Method Water cooling Electricity Demand Customizable Laser Wavelength 1080nm Observation Syatem CCD system Gas Protection Optional, Argon, Nitrogen Environmental Requirements No vibration, interference and ventilation Welding Penetration 0.1~3.0mm Application: 1. Hot sale good quality Consumer Electronics laser welding machine , Consumer electronics laser welding such as Smartphone Battery Glue Pasting, Smartphone Battery Pole Ear, Connector, Fan Motor Shell, Fingerprint Reader, etc. 2. Huiyao Consumer Electronics laser welding machine , Metal shell front spot welding, side seam welding, Spot size: 0.5mm±0.05mm, Degree of solder joint position: